巴斯夫PA66 Ultramid A3X3G7

巴斯夫PA66 Ultramid特性

Ultramid是BASF旗下半結晶型熱塑聚酰胺產(chǎn)品系列的商標。該系列包括PA 6(Ultramid B),、PA 66(Ultramid A),、PA 6/6T(Ultramid T)以及基于特種共聚酰胺的品牌,如PA 66/6。由于性能卓越,,Ultramid 已成為汽車,、電氣工程和機器結構領域中特種應用的不可或缺材料,。

Ultramid融合了多種極具吸引力的性能:

高強度和剛性

卓越的韌性

良好的彈性

出眾的耐化學性

尺寸穩(wěn)定性

低蠕變

出色的滑動摩擦性

易于加工

巴斯夫PA66 Ultramid注塑工藝

模具溫度

非增強型Ultramid 通常在40-60℃的模具溫度下加工,。增強型Ultramid 產(chǎn)品需要較高的溫度。若要獲得良好的表面質量,,且注塑件符合硬度和強度的高要求,,模具溫度應控制在80-90℃,在一些特殊情況下,,控制在120-140℃(見表1),。良好的溫度控制系統(tǒng)以及正確的模具溫度,是高品質注塑件的必要條件,。模具表面溫度會影響結晶化程度,、表面質量、收縮率,、翹曲,、尺寸公差和內應力水平。

料筒溫度

當熔體在料筒中有較長滯留時間時,,通過設置料筒加熱帶的溫度,,使其從裝料斗升至噴嘴,可實現(xiàn)溫和融化,。在較短滯留時間情況下,,也可在料筒上平緩地控制溫度。阻隔式螺桿可能需要從裝料斗至噴嘴的溫度分布,。 噴嘴應至少配有一個加熱功率為200-300 W的加熱帶,,因為向注塑模具輻射和傳導可能導致較高的熱損耗,因而存在噴嘴中熔體凝固的風險,。建議對加熱帶的控制進行監(jiān)測,。及早發(fā)出警告(如料筒上加熱帶故障),可避免螺桿破裂,。一般可通過料斗區(qū)域內的溫度控制(約80℃)改善給料行為。 |

料筒中的滯留時間

塑料在塑化料筒中的滯留時間是決定模塑質量的一個重要因素,。滯留時間過短可導致熔體的受熱不均勻,,如果過長(大于10分鐘),往往會導致熱損傷,。這將使沖擊強度受到損失,,這種損失有時可由注塑件上的變色、黑條紋或產(chǎn)品燒焦顆??闯?。

在一項測試中,通常添加不同顏色的粒料可測定滯留時間。在加工淺色Ultramid 產(chǎn)品時,,測試只需幾顆黑色粒料,。因此,滯留時間就為產(chǎn)品的循環(huán)時間和模塑上呈現(xiàn)明顯顏色差異之前所需的循環(huán)數(shù)之積,?;诶碚撋峡赡艿淖⑸淞浚瑹o法對滯留時間進行評估,。如圖4所示,,滯留時間隨著計量量增大而縮短(假定計量容量和注射循環(huán)是恒定的);當計量量超過3D時,,這種相關性就會減弱,。 |

巴斯夫PA66 Ultramid同系列型號介紹

Ultramid B3EG3 is a 15% glass fiber reinforced injection molding PA6 grade.

Ultramid B3EG6 is a 30% glass fiber reinforced injection molding PA6 grade.

Ultramid B3EG7 is a 35% glass fiber reinforced injection molding PA6 grade.

Ultramid B3K is an easy flowing, stabilized PA6 product for fast processing.

Ultramid B3S Easy flowing, finely crystalline injection moulding grade for very fast processing.

Ultramid B3WG5 is a 25% glass fiber reinforced injection molding PA6 grade with heat aging resistance.

Ultramid B3WG6 is a 30% glass fiber reinforced, heat stabilized injection molding PA6 grade.

Ultramid B3Z is an impact-modified, pigmented black, unreinforced PA6 for injection molding.

Ultramid B3ZG3 is an impact-modified, 15% glass fiber reinforced injection molding PA6 grade.

Ultramid B3ZG6 is an impact-modified, 30% glass fiber reinforced injection molding PA6 grade.

Ultramid B3M6 is a 30% mineral reinforced injection molding PA6 grade.

Ultramid A3EG3 is a 15% glass fiber reinforced injection molding PA66 grade.

Ultramid A3EG6 is a 30% glass fiber reinforced injection molding PA66 grade.

Ultramid A3EG7 is a 35% glass fiber reinforced injection molding PA66 grade.

Ultramid A3HG2 is a 10% glass fiber reinforced injection molding PA66 grade.

Ultramid A3HG5 is a 25% glass fiber reinforced injection molding PA66 grade.

Ultramid A3HG7 is a 35% glass fiber reinforced injection molding PA66 grade.

Ultramid A3K is an easy flowing, pigmented black, injection molding grade PA66.

Ultramid A3W Easy flowing, heat aging resistant injection moulding grade for fast processing.

Ultramid A3WG6 is a 30% glass fiber reinforced and heat resistance injection molding PA66 grade.

Ultramid A3WG7 is a 35% glass fiber reinforced and heat resistance injection molding PA66 grade.

Ultramid A3X2G5 Glass fibre reinforced injection moulding grade with improved flame retardance

Ultramid A3Z Impact-modified and stabilized injection moulding grade for components

Ultramid A4H High heat aging resistant, medium viscosity injection moulding grade

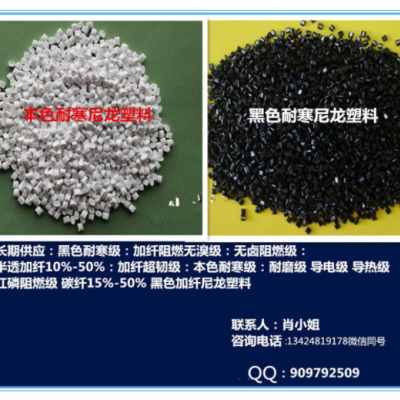

我公司長期經(jīng)營巴斯夫Ultramid系列PA66,貨源穩(wěn)定,,質量保證,,原廠原包,假一罰十,??商峁㏒GS、ROHS,、REACH,、UL黃卡、MSDS,、FDA,、COA、PDF物性表等各項數(shù)據(jù),,歡迎來電洽談,!

| 進店必搶 推薦產(chǎn)品 |